7 Interesting Facts about TMT Bars You Did Not Know About

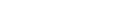

TMT bars are one of the most important construction materials that are widely used for building earthquake-resistant structures.

The ribbed TMT bars from top TMT Bar Manufacturers provide better reinforcement to any concrete structure, thus, minimizing damages during any seismic activities.

Here are 7 interesting facts about TMT bars:

1. TMT bars stand for Thermo-Mechanically Treated steel bars. As the name indicates, these are manufactured through a thermo-mechanical process, which gives these bars ultra-strength and superior quality.

2. With time, the process of manufacturing TMT bars has evolved.

Now, TMT bars are manufactured using latest technological process known as “Tempcore” technology.

In this process, the bars are subjected to sudden cooling after their final rolling process.

This sudden quenching makes the exterior of the bars extremely strong while keeping the core soft.

3. Now, while manufacturing TMT bars, the steel rods are not twisted or bent, and as a result, the bars are devoid of any residual stress, leaving them resistant to corrosion.

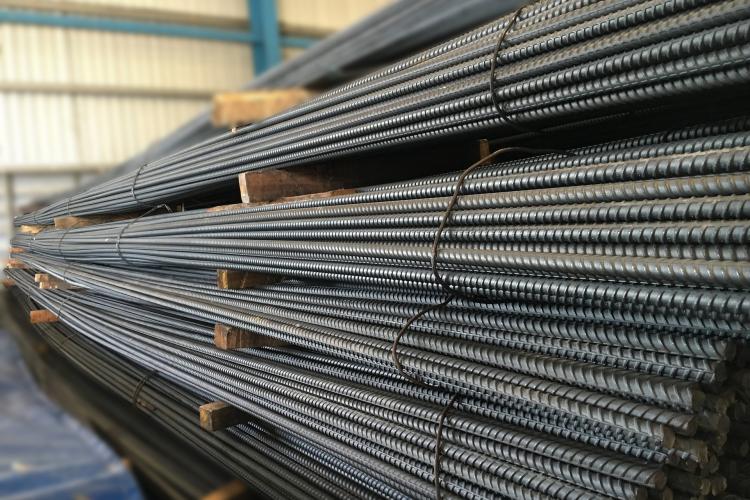

Even when the bars are exposed to water for longer periods, particularly during construction projects, rust doesn’t form on their surface.

In case of normal steel bars, corrosion is a common issue. That is why using normal steel bars hampers the structural safety of a building in short span of time.

WATCH:

4. TMT bars are extremely ductile.

These bars are available in a number of grades such as Fe-415, Fe- 500 and 550. These are much stronger than the conventional bars.

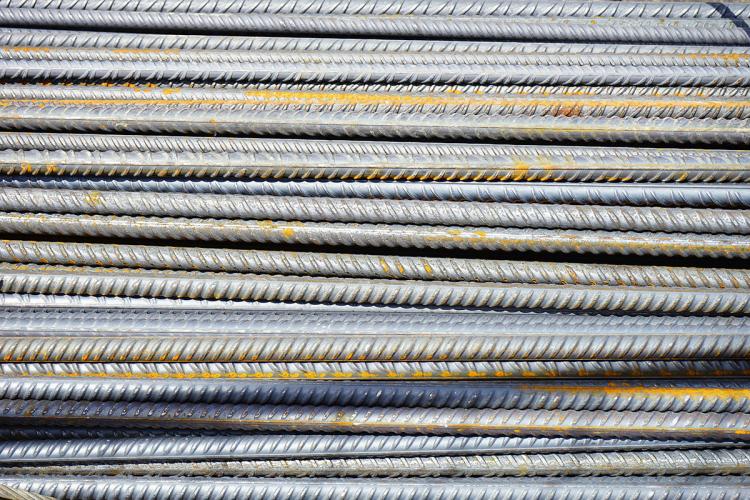

Major construction projects use high-grade TMT bars for all major projects.

There are a number of TMT bar manufacturers in India. Among them, SRMB is one of the leading TMT bar manufacturers specializing in producing high strength TMT bars.

5. TMT bars have an excellent ability to bend.

Due to their bending ability, these bars are easy to use in various construction projects.

They can be molded into various shapes and can be stretched to suit constructional measurements.

6. TMT bars provide superior resistance to earthquake and that’s why they’re one of the most preferred building materials in the earthquake-prone zones.

TMT bars give superior flexibility to a concrete structure because these have a fort inner core and a hard outer one.

7. The heat-resisting properties of TMT bars make them withstand any kind of fire hazard.

These bars can with stand heat and are, therefore, popular in the construction industry.